Storci S.p.a. designs, produces and directly sells machines and plants for pasta factories, it is difficult not to know us In the last thirty years we helped to build all the biggest dry and fresh pasta plants in Italy and in the world.

Every brand, even the best known, present on supermarket shelves, has made its pasta with our lines.

The pasta present in your cupboards (dressers) or in your refrigerators comes from our plants. We know the strength of our customers' determination, we have seen them grow and for this reason we invest our technologies to form the new generation of entrepreneurs in this sector.

We want to dedicate this page to pasta factories that have yet to be born, to start-ups, to aspiring entrepreneurs and to their training.

For aspiring entrepreneurs and aspiring entrepreneurs in the production of dry pasta, we have created two layouts that consider the various factors faced by a novice in this sector, creating a definitive start-up guide with related video tutorials.

Dried pasta is a food product by now distinctive of Italian excellence which, thanks to its ease of production, at the edge of sure interest, to the possibilities of commercial development and a relatively low initial investment, is configured as an excellent safe haven for those who want to start their own business without having to face the uncertainties of today's market.

Of course, you read that right. We are talking about one of the rare products that does not know crisis for almost more than a century. Indeed, in moments of greatest economic difficulty for the population, such as those recently lived, the consumption of pasta increases. A healthy, complete and economical product, as reported in more detail by the International Pasta Organisation.

Dry pasta then, thanks to its simplicity of packaging and the expiry of three years, allows a potentially without limits commercial development, being able to send it anywhere, also thanks to the ever-increasing online sales, to which, by now, the consumer, both Italian and foreign. is quickly getting used to it.

This page is dedicated to how many who have already had this intuition, and are now looking for a partner who can accompany them in their project one step at a time, addressing every issue that characterizes a start-up..

To do this, we have created a video tutorial where we address the topic by chapters, like in a real online course. In fact, here it is not just a question of making dry pasta but to become real entrepreneurs, able to face up to all the topics that involve a small company.

We talk about cost analysis, production techniques, plant engineering, internal organization, operational marketing, HACCP, product diversification and much more… in a single video that you can pause, watch, review, share… or fast forward.

Our testimonials... believed in us, shared their project and together we realized the dream. The success of our customers is always the greatest satisfaction! Discover all the companies that have chosen us Clicca qui!

We reasoned the first solution according to the margins that a dry pasta factory must make in order to grow. A pasta factory that produces less than 500 kg per day, will hardly be able to have the economic potential to be able to emerge. As we said before, dry pasta is a product that has no sales problems. Pasta is sold, always and in any context. What can undermine its development is its low production capacity, such as not to allow it to overcome the financial balance.

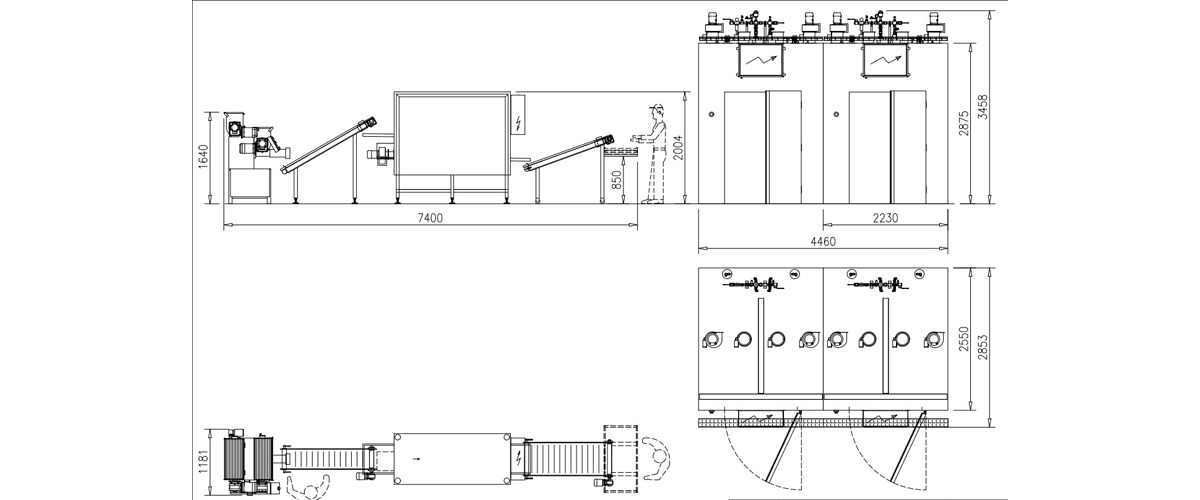

In this laboratory, which requires about 50 square meters of production area and a total of 150, a maximum of two people are needed, one for production and the other for packaging and goods storage.

Entirely made in stainless steel with double tilting basin, it allows continuous production where the rear basin prepares the dough, while the front dough extrudes the product. The overturning of the rear basin is electric. The extrusion tube is equipped with a cooling circuit with thermostat to avoid the dough from overheating during processing. Cooling happens with water and can be either closed circuit with a chiller, or continuous from the water mains. The closed circuit is highly recommended to avoid water waste. The supports for the cutting unit are mounted on the ring nut which, thanks to an inverter, can vary the length of the products.

A conveyor belt carries the product inside 5 oscillating levels trabatto which, thanks to hot water coils, pre-dry the product giving it strength first and reducing the time of the subsequent drying cycle.

The static dryers are the flagship of Storci, designed to last over the years, have a 10-year guarantee, can contain up to 33 trays of pasta compared to 25 standard, increasing the production capacity by 30%, a studied insulation in detail to maintain a drying cycle within 8 hours, thus allowing you to work even on several shifts if necessary.

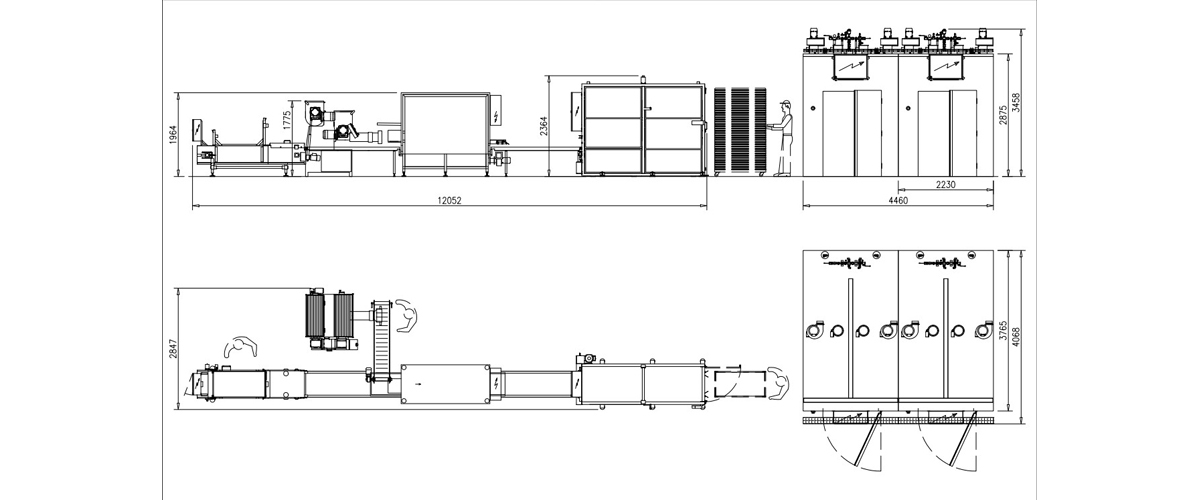

Wanting to produce 1000 kg per day, in addition to having increased the production capacity of the press, the trabatto and the cells, we have inserted automatisms to facilitate the management of moving goods. In reality, this production increase could be managed adding more staff but it would be a management mistake. The cost of automation is already justified in the first year of an extra worker's salary. In fact, between 500 and 1000 kg per day there is that first step of growth that a pasta factory must accomplish .... and it must do it well. Increasing staff in face of increased production is not an option. Just think that our 1000 kg / h automatic lines are managed by a single operator.

In this case, the press discharges directly onto the trabatto while a machine for trays advancing acts as a frame for trays, bringing them to the exit of the trabatto, where they are loaded automatically, without the aid of the operator. At the end of the line, a stacking trays creates the full trolleys that will only have to be brought to the drying rooms.

Assistance Guarantee and Safety are three aspects of a plant that are usually set aside a little by the evaluations of an entrepreneur. By assistance we mean being able to receive spare parts in a very short time. Every day without a spare part is a day without production. One day less revenue.

The warranty keeps us safe from unforeseen expenses. Especially when we are apart from the supplier company, it is important to take advantage of an extended warranty that goes well beyond the legal requirements.

Never approach a supplier company that does not respect, even in a maniacal way, all safety regulations. The pasta machines work at enormous pressures and have a high level of automation with a lot of technology in motion. Security is a moral obligation rather than a legal one..

The Fourth Industrial Revolution (or Industry 4.0) is the ongoing automation of traditional manufacturing and industrial practices, using modern smart technology. The Internet of things (IoT), improved communication and selfmonitoring, that can analyze and diagnose issues without the need for human intervention, is integrated in this process. Thanks to this system, in case of need, our technicians can intervene without being physically on the spot and the company can monitor each situation, like the alarms status and the production phase. We have also created specific working stations, undergoing further evolution, to give remote technical assistance to the Customer with the help of detectors and webcams, Storci staff can pilot the technician of the pasta factory, wherever he is. For more information watch the video!

Email us, we are here for you

You can not tell the story of Storci company without telling that one of his President. Anzio Storci begins his adventure in the world of pasta plants in 1949 as a workshop boy at Barilla, but in a few years his constant desire to learn and his natural curiosity towards life and work leads him to becoming a designer and then, a technical manager of what, from 1970 onward until today, has been the largest pasta manufacturer in the world.

Very soon the desire to go further and have his own project becomes an important goal and so he decides to start. together with five other colleagues, ParmaSei, a company operating in the sectors of diary equipment and pasta machines spare parts.

Meanwhile, having completed their studies, his sons Michele and Simone, who feel the strong enthusiasm of their father for technology and the food industry, decide to follow in their father’s footsteps and projects: this lays the foundations for the current Storci, a company that, despite the present 90 employees, has always and in any case maintained a family atmosphere. We are in 1991.

Since 1991 we have been working in the pasta machinery sector, in the pursuit of technology and innovation, making sure that the right attention is always given to tradition.

We guarantee expertise and a great cooperation. Although it is no longer a family-run business, due to the great growth of the past few years, the Company has been keeping up its original philosophy as its main feature, both towards its Partners, thanks to a successful cooperation, exchange of views and mutual trust, and especially towards its Customers.

Strada Lemignano 6, a Lemignano di Collecchio in provincia di Parma - CAP 43044

ITALIA