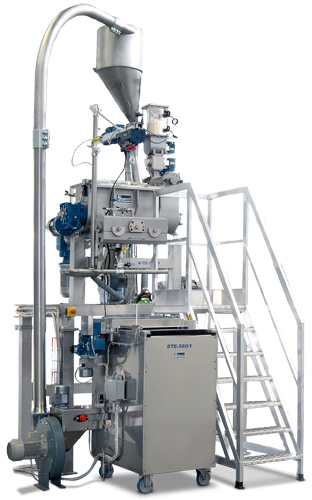

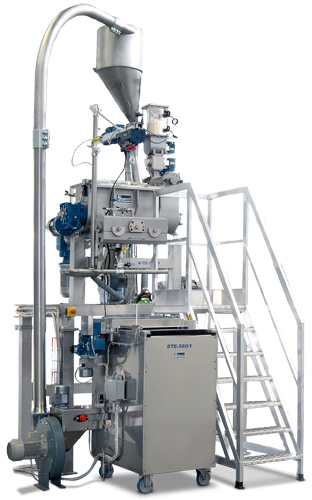

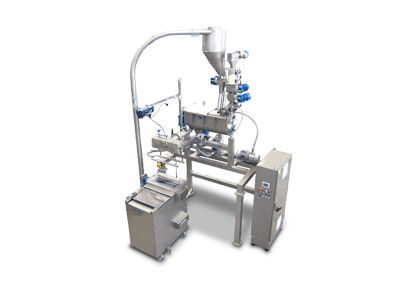

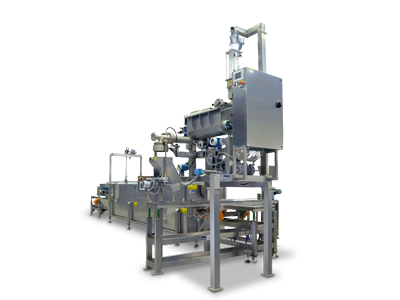

Stainless steel presses for dry and fresh pasta production particularly suitable for small and medium size industrial pasta plants.

By using special dedicated extrusion screws special pasta shapes can also be made.

Play the video

| 72.1 | |

|---|---|

| Power installed (kW) | 26 |

| Compressed air (nl min/bar) | 6/8 |

| Weight (long-short) (kg) | 1700/2100 |

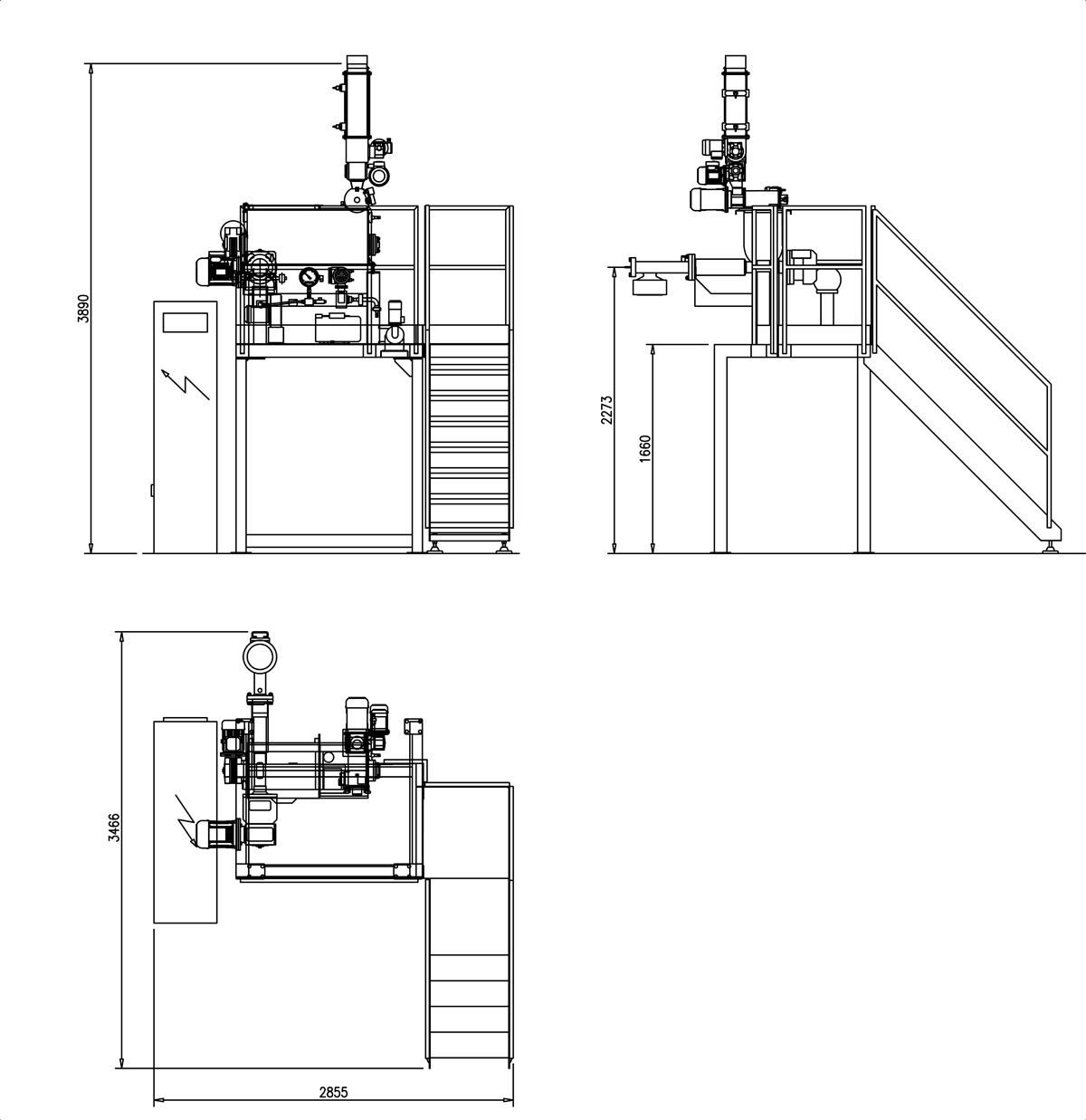

| Sizes (LxPxH) (mm) | 4200x2400x4100 |

| Mixing basin capacity (l) | 100 |

| Dimension drawing (mm) | 150/200/220/540 |

| Production (short - dry) (kg/h) | 150 |

| Production (long - dry) (kg/h) | 120 |