Our line enables you to produce the couscous you like, sticking to tradition. The line has been designed and created in single pieces so that transport and assembly times are reduced. It requires an easy and quick maintenance.

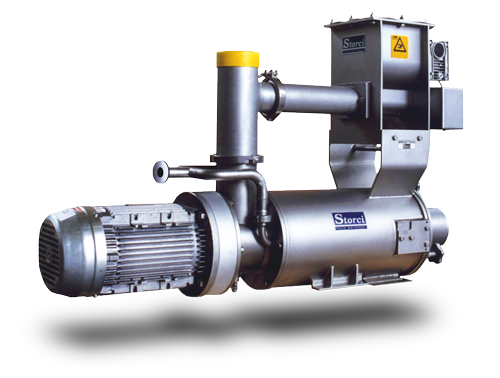

Our worldwide patented Premix®, is the best system in the market for pre-kneading. Resulting from our long experience in this sector, it can produce large quantities of dough with low energy costs, high quality result and it does not need operators.

Premix® pre-hydrates flours independently. It works continuously and produces large quantities of dough with no need of operators.

Thanks to our patented technology, il Premix® prepares the dough perfectly mixing water and flours and any other additive, with exact hydration times, without warming the dough. The result is the best possible at the moment.

It reduces the production costs thanks to very low consumptions, cleaning ease and speed and to total automatic functioning. It can produce approximately 1000 kg of dough using just one kW.

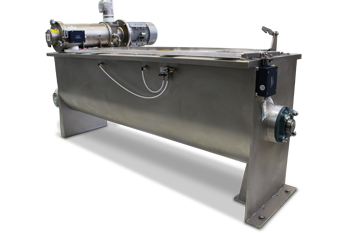

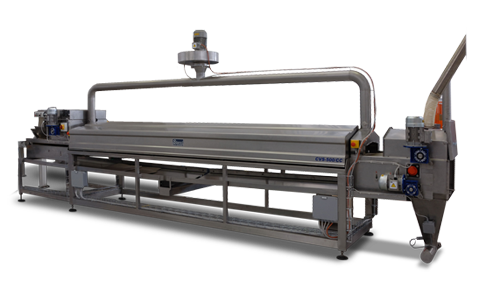

Our kneading basin makes the dough mixing it for the time needed to reach a homogeneous humidity level. There is no dough stagnation area thanks to the paddles inserted on the shaft by means of a blind hole joint system.

Stainless steel basin, shaft with paddles, motorization and several accessories: a well-tested system! The dough exiting the centrifuge falls down into the basin. Here it is mixed until it reaches an ideal homogeneous humidity level. The paddles, inserted on the shaft, make a revolving and thrusting action on the dough that is unloaded through a side opening that can be enlarged by a manually activated door. It enables, at the end of the production, to totally empty out the basin from leftovers.

All the parts in contact with the product are made of materials suitable for food contact and shaped in such a way that product stagnation is prevented.

All the system has been designed so that the mixture is conveyed, from the entrance towards the exit, through a particular routing that enables you to best exploit the sifting action of the metal sheets and hollow mesh.

In the first part of the hollow mesh which the cylinder is made up of, only the fine grind can pass through. That product is collected by hoppers and conveyor belt and brought back to the manufacturing section. In the second part of the rotating sifter, instead, only the required grind can pass through, that is also collected by hoppers and a conveyor belt that direct it to the pre-cooker.

The recovery method of the recycled product has been the subject of several improvements during the years since it is essential for the characterization of couscous.

All our couscous lines guarantee the full recycling of the product usually known as „too much coarse“ and „too much fine“, that means that does not macth the size requested by the Customer. The „right“ product, that is the one required (from 0,6 to 2 mm), keeps on moving along the line reaching the cooker and then the end of the production. The „too much coarse“ and the „too much fine“(as well as the „rightone", coming all from the rouleuse) are collected by a conveyor belt and recycled by means of a pneumatic circuit that carry them all towards the basin. Each circuit is independent: the „too much fine“, recovered by pneumatic mode, goes back to the basin through the Premix®, whereas the „too much coarse“ goes back to the basin too, although not passing through the Premix®, (because it does not need to be rehydrated ). This different routing has been designed because the humidity contained in each product may differ. Hence, both can be recovered and turn into the „right“ product.

We have been developing an innovative system indeed, which enables you to recover the line exiting powders that can settle on the line and inside the factory. More details in the Option section

Cooker: cooking phase is very much looked after in order to obtain, by the vapour injection on both the higher and lower sides of the product, a deep and homogeneous cooking. The cooker is made of highly corrosion resistant stainless steel.

The product, once entering the cooker, falls down on a mat made of peek material, that ensures a better vapour cooking. As soon as the product is inside the cooker, it is immediately levelled so that a very high layer of homogeneous product is formed and guarantees an unvarying cooking. Along the machine length there are injecting pipes that let the vapour enter the room and totally surround the product. At the cooking room exit, the product runs into a breaking lumps system; in the next phase, it falls into a sucking transport circuit that recovers the product directing it towards the dryer. The parts of the product that have not been properly crumbled, are re-selected and the lumps are brought back into the system to be crumbled as long as they reach the right grain size.

Our cooker is fed by a vapour group that can be more or less complex. In the past, the first-generation machines used a manually adjusted quantity of vapour with no instrumentation. Today we have state-of-the-art instrumentations to let you count and control the vapour used for the cooking.

the cooker cleaning system includes the connection of the water inlet directly to the machine piping. The cooker conveyor belt can be cleaned on its way, by means of a rotating brush that removes sticking crumbs. A system for the complete lift of the cooker lid is currently being studied so that the operator will be able to clean it more thoroughly. Furthermore, water used for cleaning is directed into a basin placed under the machine and carried toward a drain connected to the sewage system with a subsequent total and easy cleaning.

An extra sifting to ensure the product you like.

Il rotantino viene inserito a monte dell'essiccatoio per effettuare un'ultima setacciatura preventiva del prodotto "buono". Il prodotto ormai cotto, uscito dal cuocitore, cade nel circuito in depressione e arriva nel rotantino nelle cui maglie vengono trattenute le granulometrie troppo grosse (non sgranate bene) e vengono invece fatte passare quelle ottimali nell'essiccatoio attraverso una tramoggia. Questa è tenuta pulita costantemente da un soffio di aria calda.

The little sieve group consists of a settling cyclone (so that the just cooked “right” product can settle) and an air lock valve (that makes the product fall into the little sieve).

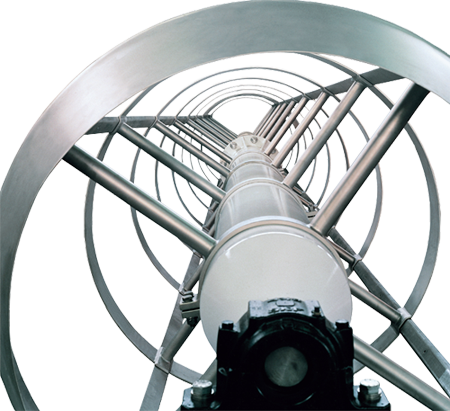

The rotating unit is a dryer particularly suitable for couscous and the type of ventilation chosen makes it even more performing.

The dryer is a strong and sturdy structure that dries the product, that means it takes away the exceeding humidity got during the cooking phase, getting it ready to be stored in the silos.

The product, hit by hot air blows, moves forward, thanks to gravity, on sloping flat surfaces, from a slot to the next one. The advancement takes place with no forces able to deform the product, because of the system peculiar geometry.

The ventilation system is essential to carry out the product technological process, in this case it is the horizontal double ventilation. The rotating movement of the barrel makes possible the regular ventilation of all the slots containing product. Thanks to the air exchange system the machine can auto-adjust so that the inner space of the dryer is controlled.

The vibrating flowing bottom cooler has an exceptional performance. As a matter of fact, using the ambient air, it can send the couscous to the sifters, with temperature that is suitable for proceeding to the next phases.

Product transport detail

The flowing bottom cooler function is cooling the product to make it ready to be immediately packed or to be stored waiting to be packed. It is a simple machine equipped with an efficient ventilation system. Its frame is strong and supported by adjustable feet for a correct levelling.

The machine has a supporting structure, a drainage to be attached to the dryer, a half cone made of steel metal sheet for distributing the product on the tray and a movement group made up of two vibrating masses. Furthermore, there is a metal sheet tray, a lower centrifugal fan and a collecting hopper to direct the product to the next section.

The cooler is full open and has no cabin. Thus the access and visibility in all its parts are guaranteed, with no risks nor dangers for the operator.

After finishing its way along the line, the couscous is now ready for being packed. Before it, however, it goes through the plansichter.

The plansichter è is composed of a cluster of sifters positioned on different levels stuck to each other and placed on a metallic surface; starting from the first level, the bigger material is discarded by means of the mesh, until the required granulometry is reached. All the system is vibrating, hanging by fibre sticks over the structure. The sifters are made of very good quality wood.

The product enters through the upper part of the machine, it is sifted by the heap of vibrating trays and by the gravity. The selected product is then directed to the storing silos.