You can configure your Nests and Lasagna Line according to your own, exclusive, need. Optional components are available to make this line a versatile and reliable product.

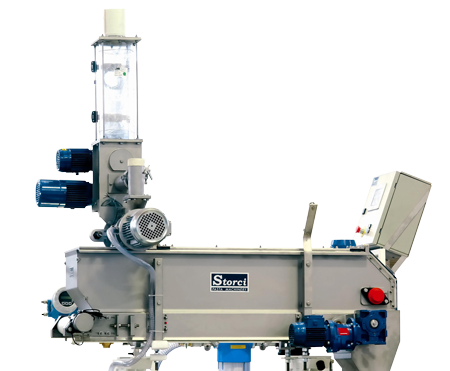

Beltmix is a patented dough mixing system that represents an important technological innovation for dry and fresh pasta, egg mixtures or with additives. Technology and sustainability, thanks to a low energy consumption. Together with Premix®, it takes the place of the traditional kneading basins with shafts.

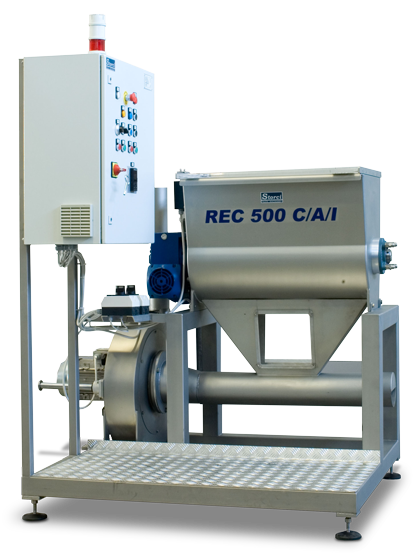

The temperature control is a system that lets you constantly check the temperature of the cylinder and the press head. All this guarantees an optimum start of your pasta production, with a shorter duration than that one of the systems with no temperature control. 100% guaranteed recipes and final product control and no wastes.

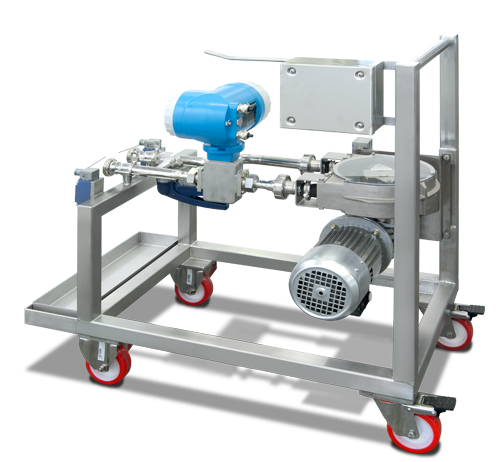

Do you have additives for your pasta? We have all the necessary systems for you. Reliability, sanitizability, dosing precision, safety and simplicity. This group of options, all wheeled, arise from the need for supplying an alternative to the ingredients dosed in the presses, compared to powder dosage.

The storage and mixture of the additives with water take place in the tanks. A couple of tanks are usually offered along with a dosing pump to safeguard the production and guarantee the times reduction, since one can be used during the dosing phase and the other one remains at disposal for preparing another mixture. The capacity can vary depending on modifications such as the press hourly production. The tank, ready with the product to be mixed, is placed near the press together with the pump (to which is joined by a flexible pipe).

Dosing pumps are available in several models (with lobes, peristaltic pumps, etc) depending on the type of plant. The pump is equipped with a capacity measurer handling the pump speed, thus enabling an optimal dosage.

Automatic cleaning system of the additives plant by C.I.P.

Compact group for the cleaning of piping and additives dosing plants, strongly recommended with egg dosage (due to its bacteriological degree of severity). Hence in this case the sanitizing process must be monitored periodically for each part in contact with the product, by C.I.P. group.

Whenever you have to dose solid additives such as spinach, powdered eggs, tomatoes, turmeric, vitamins, etc., you can resort to solid additives dosing group. The choice might lie between a doser with one screw or with two screws (when the capacities are small or the products stick to each other). You could also opt for either a volumetric doser ( for non-hygroscopic raw materials such as flour or semolina) or a gravimetric one (for products such as tomatoes, vitamins, etc). Both can be fed manually or automatically, according to the Customer’s needs.

Thanks to our pre-dryer, you can carry out the pre-drying phase that is essential in the nests production for keeping and improving the shape. Its modulating structure has been thought so that the length and humidity are set up to meet the Customer’s needs.

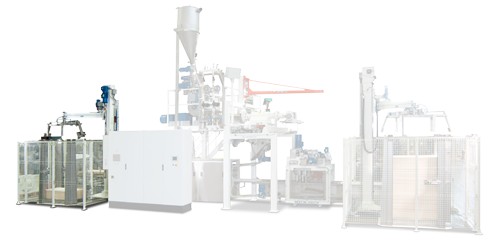

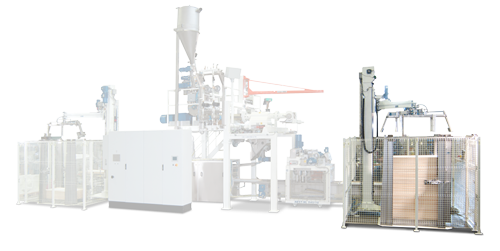

You can choose between a trays stacking machine, ROBO-T, to be placed at the end of the line so that you can reduce your staff to two workers only, or an automated system, ROBO XI/XD, with an unstacking machine at the beginning and a stacking machine at the end of the line with no staff assistance. These systems can be compatible to all Storci lines and to other ones as well.

It is suitable for producing short and special pasta and enables to reduce the staff working on the line. Specifically made for all Storci plants, it is ideal for other lines as well.

Disimpilatore telai a gestione robotizzata, consente la gestione automatica dei telai per le linee di pasta corta, nidi e lasagne senza ausilio di operatori. Migliora la qualità del tuo lavoro, innovazione & risparmio per soddisfare ogni esigenza.

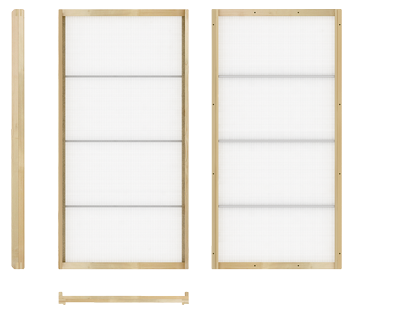

Double choice to dry your pasta: choose between the traditional wooden tray and the aluminium tray, depending on your production preferences. Buy your plant with the trays: start your production from the very first day!

Fir wood and anti-hydrolysis polyester mesh. Two available standard models to dry lasagna, standard short pasta and big shapes (e.g.conchiglioni). If you choose the tradition: the wood.

Key words: precious and resilient material. This is the alternative for those choosing innovation. Two available models, find out their technical features and benefits!